Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

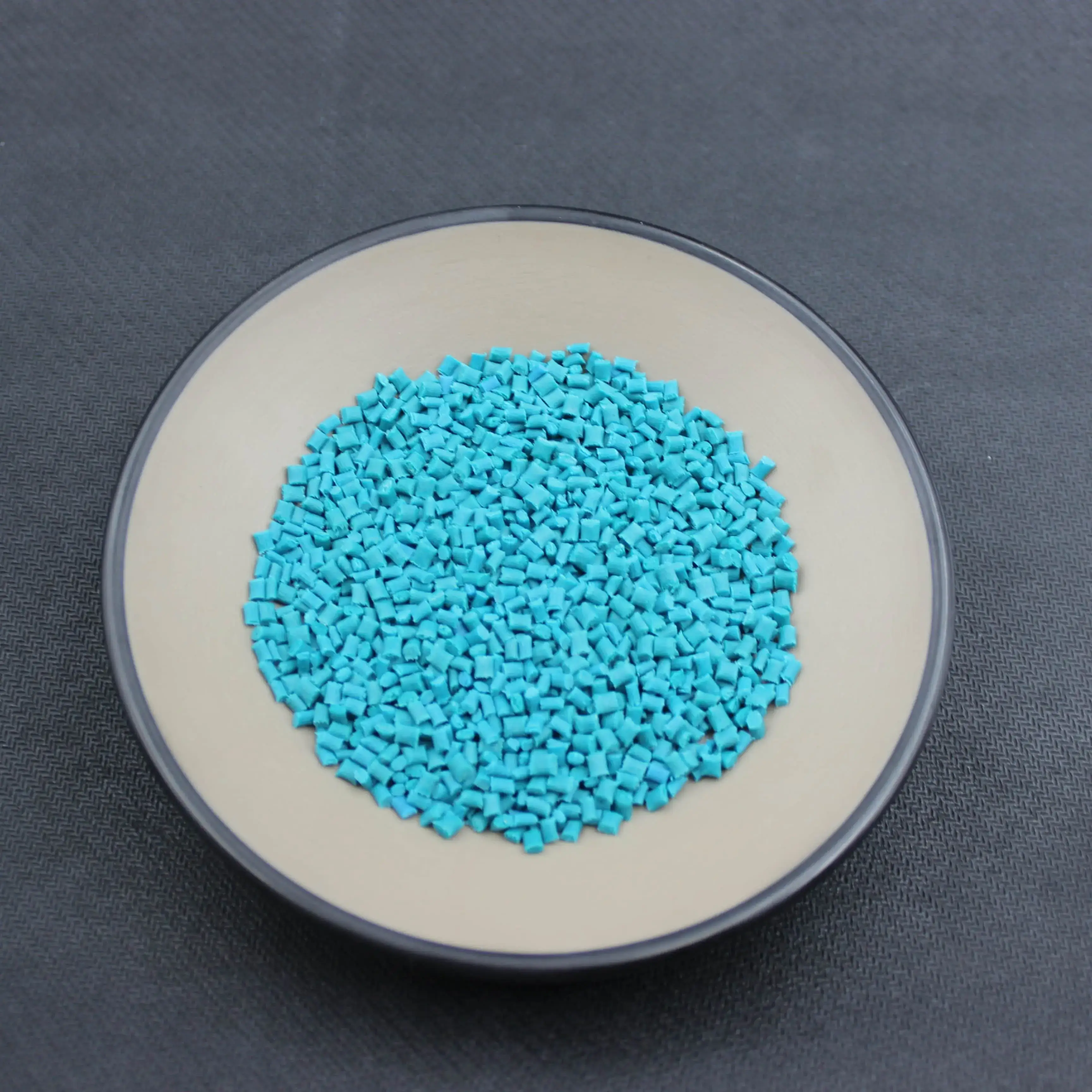

Analysis of Polyphenylene Sulfide (PPS) Material

Polyphenylene Sulfide (PPS) is a high-performance engineering thermoplastic known for its excellent heat resistance, chemical stability, and mechanical strength. It is widely used in demanding industries such as automotive, electronics, and aerospace. As industries increasingly demand materials with enhanced properties, PPS has become an ideal replacement for traditional materials like metal and thermosetting plastics. This article provides an in-depth analysis of PPS’s molecular structure, key properties, modification techniques, main applications, and future development trends.

I. Molecular Structure and Classification of PPS

1. Molecular Structure

PPS is an aromatic polymer synthesized through a nucleophilic substitution reaction between p-dichlorobenzene and sodium sulfide in a solvent medium.

This unique linear aromatic structure gives PPS exceptional heat resistance, chemical stability, and mechanical integrity. The benzene rings in the main chain provide rigidity and dimensional stability, while the thioether bonds enhance the material's heat and solvent resistance.

2. Classification of PPS

Based on the polymerization process and processing properties, PPS is classified into two types:

-

Linear PPS: Characterized by higher ductility and toughness, suitable for injection molding and extrusion processes, making it ideal for producing high-precision components.

-

Cross-linked PPS: Offers higher rigidity, heat resistance, and solvent resistance, making it suitable for coatings, composite materials, and specialized applications II. Key Properties of PPS Material

1. Heat Resistance

PPS exhibits excellent thermal properties:

-

Heat Deflection Temperature (HDT): 260-280°C

-

Continuous Service Temperature: 200-220°C

These properties allow PPS to maintain structural integrity in harsh, high-temperature environments, making it ideal for mechanical parts exposed to heat.

2. Chemical Stability

PPS is insoluble in nearly all solvents and resists a wide range of acids, bases, salts, and organic solvents, making it suitable for corrosive environments like chemical processing and fuel systems.

3. Mechanical Properties

-

High Rigidity and Strength: PPS exhibits excellent creep resistance and dimensional stability, making it ideal for precision and complex component manufacturing.

-

Wear Resistance and Self-lubrication: PPS has a low friction coefficient and exceptional wear resistance, making it suitable for sliding components and bearings in high-friction applications.

4. Electrical Properties

PPS provides superior electrical insulation and maintains stable dielectric properties under high temperature and humidity conditions, making it ideal for electrical and electronic components.

III. Modification Techniques for PPS

Despite its excellent base properties, PPS often requires modification to enhance its processability and specific performance characteristics. Common modification techniques include:

1. Glass Fiber Reinforcement (GF)

Incorporating glass fibers significantly improves PPS’s mechanical strength, thermal stability, and dimensional accuracy, making it suitable for automotive engine components and electronic connectors.

2. Mineral Filling

Adding talc, barium sulfate, or other mineral fillers enhances creep resistance, wear performance, and reduces molding shrinkage, making it ideal for high-precision electronic components.

3. Conductive and Anti-static Modification

By adding carbon fibers, carbon black, or metal powders, PPS can be made conductive or anti-static, suitable for electronic device casings and IC packaging requiring electrostatic protection.

4. Hydrolysis and Flame Retardant Modification

Special additives can improve hydrolysis resistance and provide flame-retardant properties, making PPS suitable for high-temperature, high-humidity environments in household appliances and electronic devices.

1. Automotive Industry

PPS’s resistance to heat, oil, and chemicals makes it indispensable for manufacturing:

-

Engine components (throttle bodies, fuel lines, intake manifolds)

-

Electrical systems (sensor housings, relay bases, connectors)

2. Electronics and Electrical Industry

PPS’s high dielectric strength and thermal stability make it ideal for:

-

High-temperature connectors, coil bobbins, PCB supports

-

LED heat dissipation substrates and insulation parts

3. Aerospace Industry

The lightweight, high strength, and radiation resistance of PPS make it suitable for:

-

Structural components

-

Protective casings for electronic equipment

4. Industrial Equipment

PPS’s corrosion resistance and wear performance are valuable in chemical and mechanical applications such as:

-

Chemical processing equipment

-

Pump and valve components, filtration systems

V. Market Outlook and Future Trends of PPS Material

1. Drivers of Demand Growth

-

New Energy Vehicles (NEVs): PPS is a lightweight alternative to metals, supporting the industry’s push for vehicle weight reduction.

-

5G and Semiconductors: PPS’s stability in high-frequency and high-temperature environments makes it ideal for 5G base stations and chip packaging.

-

Green and Sustainable Development: PPS’s recyclability aligns with global sustainability goals.

2. Technological Innovation Directions

-

Ultra-pure PPS: Designed for use in semiconductors and medical devices requiring extremely high purity levels.

-

Low-dielectric PPS: Meets the demands of 5G communications by minimizing signal loss.

-

Smart Composite Materials: Combining PPS with nanomaterials enhances functionalities such as thermal conductivity and electromagnetic shielding.

With its exceptional heat resistance, chemical stability, mechanical strength, and electrical properties, PPS has become a pivotal material in the high-performance engineering plastics sector. As industrial demands evolve, modification technologies and applications of PPS will continue to expand, especially in new energy vehicles, 5G communication, and aerospace. PPS is poised to play an indispensable role in these cutting-edge markets.