Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Causes and Solutions for Defective Ejection in Injection Molded Products

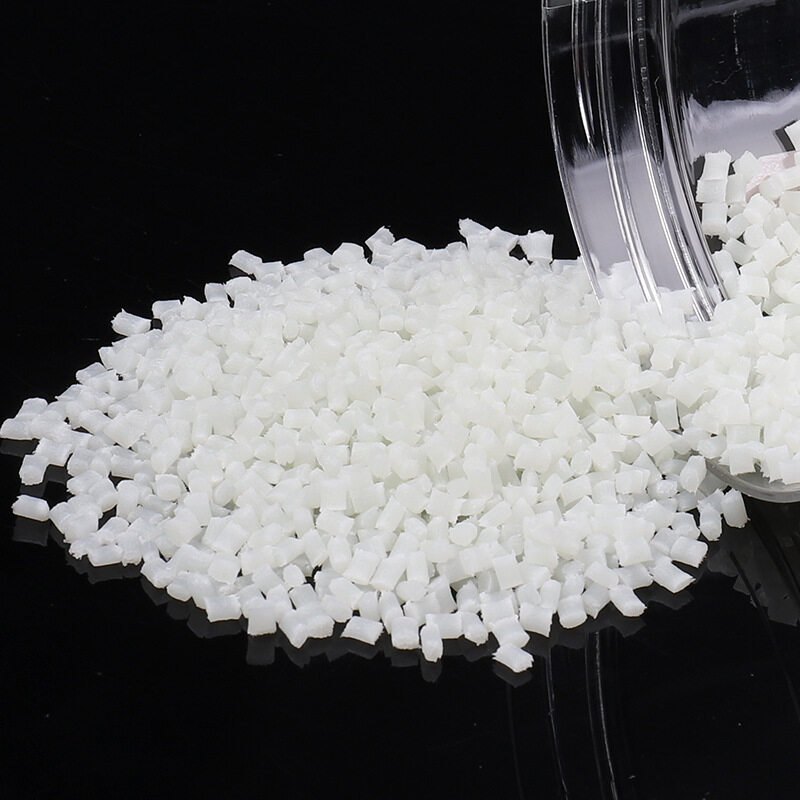

Adding fillers such as glass fibers and toughening agents to nylon can significantly enhance the mechanical properties of the material. However, during the injection molding process of glass fiber-reinforced nylon, a phenomenon known as "floating fibers" often occurs. Floating fibers, also called exposed fibers, refer to glass fibers appearing on the surface of the product, creating a relatively rough texture.

The main reasons for the formation of floating fibers are as follows:

-

Poor compatibility between glass fibers and nylon:

Due to the frictional shear forces exerted by the screw, nozzle, runner, and gate on the plastic melt during flow, differences in local viscosity are created. This process also damages the interface layer on the surface of the glass fiber. As the melt viscosity decreases and the interface layer is more severely damaged, the bonding strength between the glass fiber and the resin decreases. When the bonding strength decreases to a certain extent, the glass fiber breaks free from the resin matrix and gradually accumulates on the surface, leading to exposure. -

Difference in specific gravity between glass fibers and the base material:

During the flow of the plastic melt, the differences in flowability and density between glass fibers and resin result in a tendency for them to separate. Glass fibers float to the surface while the resin sinks inward, causing the phenomenon of exposed fibers. -

Fountain effect:

When the nylon melt is injected into the mold cavity, a "fountain" effect occurs, causing glass fibers to flow from the interior to the outer surface and come into contact with the mold surface. Due to the lower temperature of the mold surface, the glass fibers with rapid cooling are instantly frozen. If they are not fully surrounded by the melt in time, they will be exposed on the surface, forming "floating fibers".

To address the issue of floating fibers in glass fiber-reinforced nylon, the following solutions can be considered:

-

Mold design:

Deliberately create a matte or textured surface on the product's appearance to reduce the visual impact of floating fibers. -

Improving the compatibility between glass fibers and nylon:

Adding additives such as compatibility agents, dispersants, and lubricants to the molding material, including silane coupling agents, maleic anhydride grafted compatibility agents, fatty acid lubricants, and some domestically produced or imported anti-floating fiber agents. -

Improving molding process conditions:

- Increase filling speed: By increasing the speed, although there are differences in flow rates between glass fibers and plastics, the relative speed difference is reduced compared to high-speed injection, minimizing the likelihood of floating fibers.

- Raise mold temperature: Increasing the mold temperature reduces the contact resistance between glass fibers and the mold, minimizing the speed difference between glass fibers and plastics. This ensures a thicker molten layer during plastic flow, with thinner skin layers on both sides, similar to how a smooth riverbank cannot retain branches.

- Lower the temperature of the screw metering section and reduce the amount of solvent: This minimizes the possibility of separation between plastics and glass fibers. While this has minimal impact on floating fibers, it effectively resolves issues such as scorching. This is because the addition of glass fibers easily blocks the exhaust passage, making it difficult to exhaust at the end, and glass fibers are prone to combustion in high-pressure, high-oxygen environments.