Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

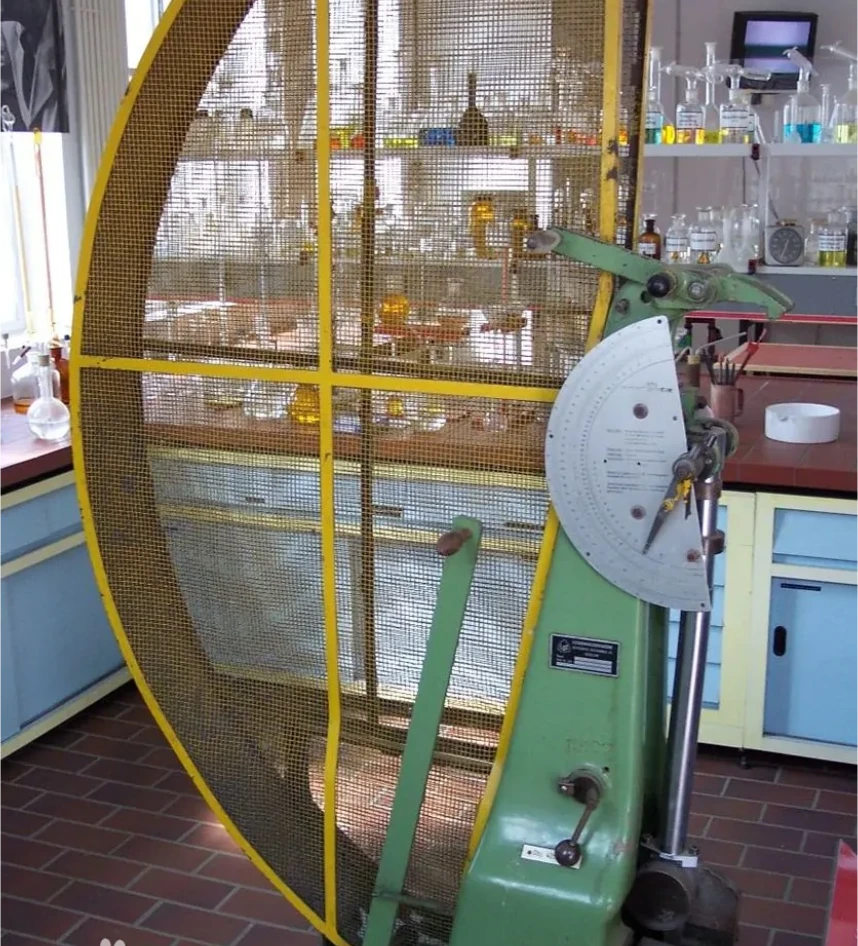

Charpy Impact Strength:Notched or Un-notched

The difference between Notched Charpy Impact Strength and Un-notched Charpy Impact Strength lies in the presence of a notch in the specimen.

For Notched Charpy Impact Strength, a V-shaped notch is machined into the specimen. The specimen is then loaded with a compressive force at a specific impact velocity, and the maximum force sustained by the specimen before fracture is recorded. This test measures the energy absorbed by the specimen before failure and provides information on the material's resistance to brittle fracture. The presence of the notch increases the stress concentration and promotes brittle fracture behavior.

On the other hand, for Un-notched Charpy Impact Strength, the specimen does not have a notch. It is a rectangular bar with rounded corners. The specimen is also loaded with a compressive force at a specific impact velocity, and the maximum force sustained by the specimen before fracture is recorded. This test measures the energy absorbed by the specimen before failure and provides information on the material's resistance to ductile fracture. The absence of a notch reduces the stress concentration and promotes ductile fracture behavior.

In summary, Notched Charpy Impact Strength measures the resistance to brittle fracture by loading a notched specimen, while Un-notched Charpy Impact Strength measures the resistance to ductile fracture by loading a non-notched specimen.