Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

PA66+30% long carbon fiber material: excellent thermal stability and high performance

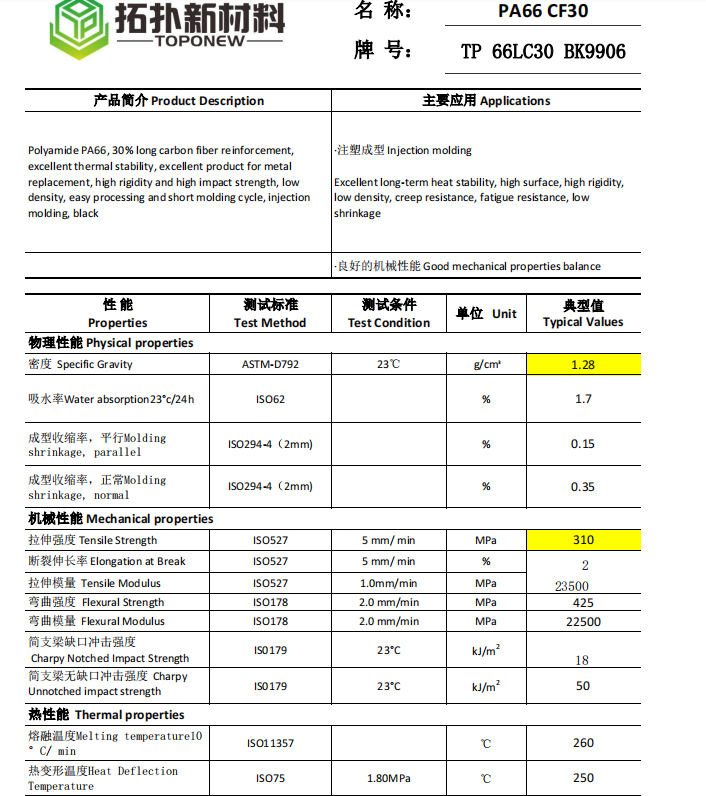

In modern industry, with the continuous advancement of technology, the performance requirements for plastic materials are also increasing. Especially in application scenarios that require high rigidity, high impact strength and high temperature resistance, PA66 (polyamide 66) combined with 30% long carbon fiber reinforcement has become an ideal choice for replacing metal materials with its excellent performance. PA66+30% long carbon fiber material not only has the strength of metal, but also has the lightness and good processability of plastic, meeting the needs of many industries for high-performance materials.

Product Overview

PA66+30% long carbon fiber is a polyamide material reinforced with long carbon fiber, which has excellent thermal stability, high rigidity, good impact strength and low density. This material can show excellent performance in the injection molding process, suitable for products with high requirements for strength, rigidity and high temperature resistance, and is widely used in the field of engineering plastics that require metal replacement.

Main performance characteristics

Excellent thermal stability: PA66+30% long carbon fiber material has excellent high temperature resistance and can maintain its physical properties unchanged under long-term exposure to high temperature environment.

High rigidity and low density: Compared with traditional metal materials, PA66+30% long carbon fiber has significant lightweight advantages while retaining the characteristics of high rigidity, which is suitable for applications with high strength requirements.

Tensile strength up to 310 MPa: The tensile strength of this material can reach 310 MPa, which can withstand large tensile loads and is suitable for products requiring high mechanical properties.

Creep resistance and fatigue resistance: This material can show excellent creep resistance and fatigue resistance under long-term load, avoiding deformation problems in long-term use and extending product life.

Low shrinkage: During the injection molding process, the material shows a low shrinkage rate, ensuring the dimensional accuracy and surface quality of the product.

Easy processing and molding: PA66+30% long carbon fiber material can be applied to injection molding process, with short molding cycle and high production efficiency, which can meet the needs of mass production.

Application fields

The excellent properties of PA66+30% long carbon fiber materials make it widely used in many fields, especially in applications that require high strength, high temperature resistance, low weight and high rigidity. The following are some specific application scenarios and industries:

Automotive industry

In the automotive industry, PA66+30% long carbon fiber materials are widely used in engine components, transmission systems, body parts, etc. By using this material, automakers are able to reduce the weight of components, thereby improving fuel efficiency and enhancing the strength and durability of components. For example, automobile engine housings, drive shafts, wheels and other components often use this material.

Electronic and electrical industry

In the field of electronic and electrical, PA66+30% long carbon fiber materials are used to manufacture high-performance connectors, electrical component housings, heat sinks, etc. Because the material has good thermal stability, it can effectively cope with the high temperature environment generated during the operation of electronic equipment, ensuring the stability and long life of the equipment.

Aerospace industry

In the field of aerospace, PA66+30% long carbon fiber materials are widely used in aircraft structural components, cabin equipment, engine housings, etc. due to their light weight and high strength characteristics. By using this material, the overall weight of the aircraft can be effectively reduced, fuel efficiency can be improved, and the high temperature resistance and impact resistance of aircraft components can be enhanced.

Mechanical equipment industry

In the field of mechanical equipment, PA66+30% long carbon fiber materials are often used to manufacture gears, bearings, transmission devices and other components. Due to its excellent mechanical strength and wear resistance, it can maintain good stability and durability in high-load and high-impact working environments.

Consumer goods industry

PA66+30% long carbon fiber materials are also widely used in the field of consumer goods, such as high-end sports equipment, tool housings, and home appliance accessories. These products require materials to be light, strong and durable, and PA66+30% long carbon fiber perfectly meets these needs.

Military and protective equipment

In the military field, PA66+30% long carbon fiber materials are often used to manufacture high-strength, impact-resistant protective equipment, such as bulletproof vests, tactical equipment housings, etc. The high strength and impact resistance of this material enable it to provide reliable protection in extreme environments.

Environmental certification and quality assurance

PA66+30% long carbon fiber material complies with international environmental standards and has obtained RoHS and REACH certification to ensure product compliance in terms of environmental protection and safety. This enables the material to be widely used worldwide to meet the environmental protection requirements of various industries.

Conclusion

With the increasing demand for high-performance materials in industry, PA66+30% long carbon fiber material has become an indispensable material in many industries due to its excellent thermal stability, high rigidity, impact resistance and high tensile strength. Whether in the automotive, aviation, electronics, machinery, or consumer goods fields, PA66+30% long carbon fiber material has demonstrated its wide application prospects. For companies seeking a high-performance material that combines strength, temperature resistance and impact resistance, PA66+30% long carbon fiber is undoubtedly an ideal choice.