Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Tailoring Performance: The World of Customized PP Resins

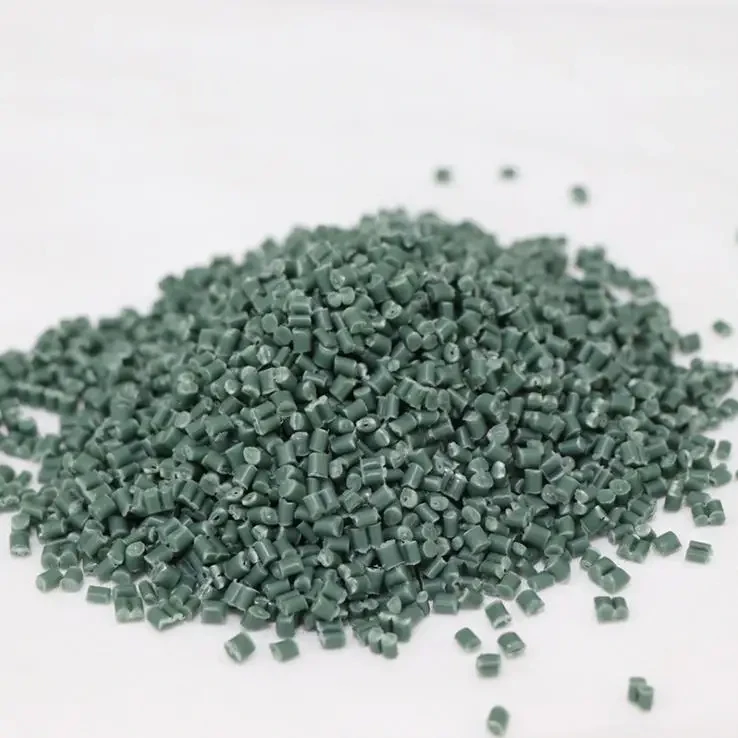

In the realm of polymer sciences, the customization of materials to fit specific industry needs has become a cornerstone of innovation. Customized PP resins, or polypropylene resins tailored to specific applications, represent a significant leap forward in material engineering. As a versatile and widely used plastic, PP resins have been adapted in countless ways to enhance their properties and functionality for various applications.

The Art of Customizing PP Resins

Customized PP resins are the result of a meticulous process where the base properties of polypropylene are altered to meet the unique demands of customers. This customization can involve altering the flow rate of the resin, its impact resistance, stiffness, clarity, or even adding special additives to give the material unique characteristics such as UV resistance or anti-static behavior.

Advantages of Customized PP Resins

The primary advantage of using customized PP resins lies in their ability to provide solutions that standard resins cannot. For instance, in the automotive industry, a PP resin customized for high impact and heat resistance can lead to safer and more durable components. In the packaging industry, a PP resin with enhanced clarity and rigidity can result in more attractive and sturdy consumer packaging.

Customization Meets Sustainability

In today’s eco-conscious market, customized PP resins also play a pivotal role in sustainability. By engineering resins that are easier to process, manufacturers can reduce energy consumption during production. Additionally, customizing PP resins for improved longevity and recyclability aligns with global efforts to minimize plastic waste and promote a circular economy.

The Process of Customizing PP Resins

The journey to create a customized PP resin begins with understanding the client’s needs. This collaborative approach involves discussions, prototyping, and testing to ensure that the final product not only meets but exceeds expectations. State-of-the-art laboratories and experienced chemists work together to tweak the polymerization process and additive formulations to achieve the desired resin characteristics.

Applications of Customized PP Resins

The applications for customized PP resins are as diverse as the modifications themselves. From medical devices requiring biocompatibility and sterilization stability to consumer goods that demand aesthetic appeal and durability, customized PP resins are shaping products across industries. Even in the field of high-performance textiles, PP resins customized for fiber production are creating fabrics with unique properties.

Partnering with Clients for Customized Solutions

As manufacturers of customized PP resins, the goal is to become a trusted partner to clients. This means not only delivering a product that fits their specifications but also providing ongoing support, technical expertise, and a commitment to continuous improvement. By staying at the forefront of polymer technology and market trends, manufacturers can ensure that their customized PP resins remain relevant and in demand.

Conclusion

Customized PP resins represent a fusion of customer-centric focus and advanced material science. By tailoring the properties of polypropylene to specific needs, manufacturers are unlocking new possibilities and driving innovation across various sectors. Whether it’s enhancing product performance, meeting stringent industry standards, or contributing to environmental sustainability, customized PP resins are proving to be a key ingredient in the recipe for success.