Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Understanding the Advantages, Disadvantages, and Molding Applications of Nylon Plastic

Introduction

Welcome to the comprehensive guide on Understanding the Advantages, Disadvantages, and Molding Applications of Nylon Plastic. As a leading manufacturer of modified plastic pellets, TOPONEW specializes in producing high-quality PA6 pellets for various industries. This article will delve into the versatile applications of PA6 pellets in ODM services, innovative solutions tailored to specific requirements, and bulk supply options. Join us as we explore the benefits and challenges associated with PA6 pellets, and discover how they can enhance your plastic manufacturing processes.

Nylon

Nylon (Nylon, Polyamide, PA for short) refers to a plastic composed of polyamide resin. This type of resin can be produced by condensation polymerization of diamines and dibasic acids, or by ring-opening polymerization of lactams formed after dehydration of amino acids. Unlike PS, PE, PP, etc., PA does not gradually change as the heating temperature increases. Softening, but softening in a narrow temperature range close to the melting point, the melting point is obvious, melting point: 215-225°C. Flow occurs once the temperature is reached.

There are many varieties of PA, mainly including PA6, PA66, PA610, PA11, PA12, PA1010, PA612, PA46, PA6T, PA9T, MXD-6 aromatic amide, etc. PA6, PA66, PA610, PA11 and PA12 are the most commonly used.

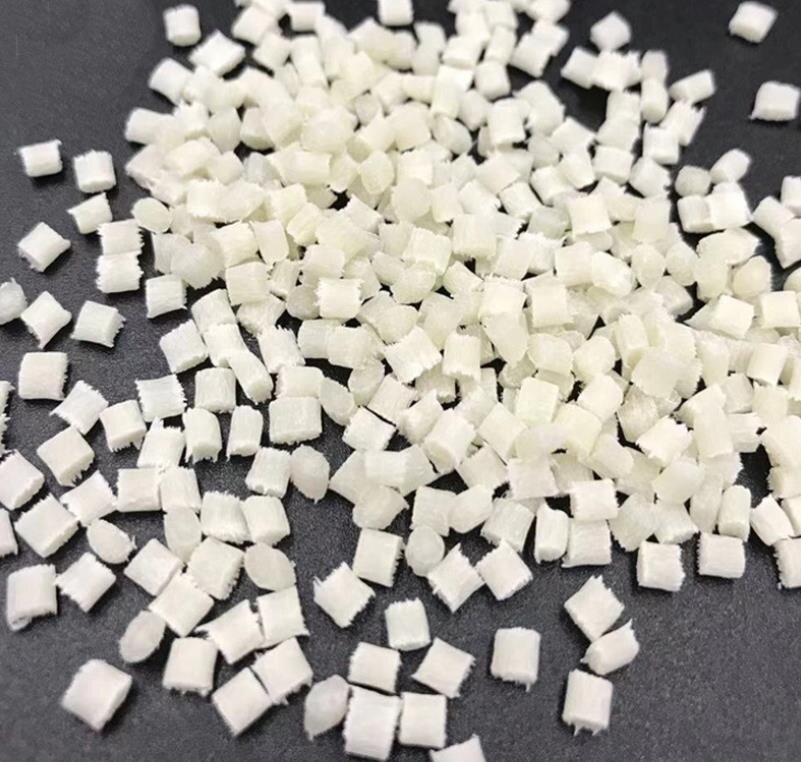

Nylon engineering plastics appear to be horny, tough, bright, white (or milky white) or yellowish, transparent or translucent crystalline resin, which can be easily painted into any color. As an engineering plastic, the molecular weight of nylon is generally 15,000-30,000. Their density is slightly greater than 1, density: 1.14-1.15g/cm3. Tensile strength: > 60.0MPa. Elongation: > 30%. Bending strength: 90.0MPa. Notched impact strength: (kJ/m2) >5.

The shrinkage rate of nylon is 1% to 2%. Pay attention to the dimensional changes due to moisture absorption after molding. The water absorption rate is 100%. It can absorb 8% when the relative moisture absorption is saturated. The use temperature can be between -40~105℃. Melting point: 215~225℃. The suitable wall thickness is 2~3.5mm. The mechanical properties of PA, such as tensile and compressive strength, change with temperature and moisture absorption, so water is relatively a plasticizer for PA. After adding glass fiber, its tensile and compressive strength can be improved. About 2 times, the temperature resistance is also improved accordingly. PA itself has very high wear resistance, so it can be operated continuously without lubrication. If you want to get special lubrication effect, you can add sulfide to PA.

2. Main advantages of PA performance

It has high mechanical strength, good toughness, and high tensile and compressive strength. The specific tensile strength is higher than that of metal, and the specific compressive strength is comparable to metal, but its rigidity is not as good as metal. The tensile strength is close to the yield strength and is more than twice as high as ABS. It has strong ability to absorb impact and stress vibration, and its impact strength is much higher than that of ordinary plastics, and better than acetal resin.

Outstanding fatigue resistance, the parts can still maintain their original mechanical strength after repeated bending. PA is often used in common escalator handrails, new bicycle plastic rims and other occasions where the cyclic fatigue effect is extremely obvious.

High softening point and heat-resistant (such as nylon 46, etc., highly crystalline nylon has a high heat distortion temperature and can be used at 150 degrees for a long time. After PA66 is reinforced with glass fiber, its heat distortion temperature reaches more than 250 degrees).

The surface is smooth, the friction coefficient is small, and it is wear-resistant. It has self-lubricating properties and low noise when used as movable mechanical components. It can be used without lubricant when the friction is not too high. If lubricant is really needed to reduce friction or help dissipate heat, water, oil, grease, etc. can be selected. Therefore, it has a long service life as a transmission component.

It is corrosion-resistant, very resistant to alkali and most salt liquids, and is also resistant to weak acids, engine oil, gasoline, aromatic hydrocarbons and general solvents. It is inert to aromatic compounds, but not resistant to strong acids and oxidants. It can resist the corrosion of gasoline, oil, fat, alcohol, weak alcohol, etc. and has good anti-aging ability. It can be used as packaging material for lubricating oil, fuel, etc.

It is self-extinguishing, non-toxic, odorless, has good weather resistance, is inert to biological erosion, and has good antibacterial and anti-fungal abilities.

Has excellent electrical properties. Good electrical insulation. Nylon has high volume resistance and high breakdown voltage resistance. It can be used as power frequency insulation material in dry environments. It still has good electrical insulation even in high-humidity environments.

The parts are light in weight, easy to dye and easy to shape. Because of its low melt viscosity, it can flow quickly. It is easy to fill the mold, has a high solidification point after filling, and can be quickly shaped, so the molding cycle is short and the production efficiency is high.

3. Main disadvantages of PA performance

Easily absorbs water. It has high water absorption, and the saturated water can reach more than 3%. It affects the dimensional stability and electrical properties to a certain extent, especially the thickening of thin-walled parts. Water absorption will also greatly reduce the mechanical strength of the plastic. When selecting materials, the influence of the use environment and the matching accuracy with other components should be taken into consideration. Fiber reinforcement can reduce the water absorption of the resin, allowing it to work under high temperatures and high humidity. Nylon has a very good affinity with fiberglass. It is often used to make combs, toothbrushes, clothes hooks, fan ribs, mesh bag ropes, fruit packaging bags, etc. Non-toxic, but not in long-term contact with acids and alkalis. It is worth noting that after adding glass fiber, the tensile strength of nylon can be increased by about 2 times, and the temperature resistance is also improved accordingly.

Lightfastness is poor. In a long-term high-temperature environment, it will undergo oxidation with oxygen in the air. The color will initially turn brown, and then the surface will break and crack.

Injection molding technology has strict requirements: the presence of trace amounts of moisture will cause great damage to the molding quality; the dimensional stability of the product is difficult to control due to thermal expansion; the presence of sharp corners in the product will cause stress concentration and reduce the mechanical strength; if the wall thickness is not Uniformity will lead to distortion and deformation of the parts; high equipment accuracy is required during post-processing of the parts.

It will absorb water and alcohol and swell. It is not resistant to strong acids and oxidants and cannot be used as acid-resistant materials.

4. Purpose

Nylon is mainly used in the automotive industry, electrical and electronic industry, transportation industry, machinery manufacturing industry, wire and cable communication industry, films and daily necessities. It manufactures various bearings, gears, circular gears, cams, bevel gears, oil pipes, oil reservoirs, Protective cover, support frame, wheel cover, deflector, fan, air filter housing, radiator water chamber, brake pipe, engine hood, door handle. Bearings, gears, pulley pump impeller, blades, high-pressure sealing rings, Pad, valve seat, bushings, oil pipes, oil reservoirs, ropes, transmission belts, grinding wheel adhesives, battery boxes, electrical coils, cable joints, various rollers, pulleys, pump impellers, fan blades, worm gears, propellers, screws, nuts, oil-resistant sealing gaskets , oil-resistant containers, shells, hoses, cable sheaths, shears, pulley sets, planer slides, electromagnetic distribution valve seats, cold aging equipment, liners, bearing cages, various oil pipes and pistons on cars and tractors , ropes, transmission belts, zero fog materials for textile machinery and industrial equipment, as well as daily necessities and packaging films, etc.

The output of packaging tapes and food films (high-temperature films for cooked foods and low-temperature films for soft drinks) is also quite large.

5. Forming and post-processing

Except for transparent nylon, other nylons are crystalline plastics with high melting points, narrow melting temperature ranges, and poor thermal stability. PA is easy to absorb moisture. During the molding process of wet nylon, the viscosity drops sharply and silver threads appear on the surface of the product mixed with bubbles. The mechanical strength of the resulting product decreases, so the material must be dried before processing. It can be dried at 80~110℃ 6 hours, the allowable moisture content during molding is 0.1% for nylon 6 and nylon 66, 0.15% for nylon 11, and 0.1% to 0.15% for nylon 610, and the maximum cannot exceed 0.2%. Note that PA plastics can easily cause discoloration when dried above 90°C.

PA has good fluidity and is easy to overflow. It is recommended to use a self-locking nozzle and heat it. At the same time, due to the fast condensation speed of the solution, materials should be prevented from blocking the nozzles, flow channels, gates, etc., causing insufficient products. The mold overflow value is 0.03, and the melt viscosity is sensitive to changes in temperature and shear force, but is even more sensitive to temperature. To reduce the melt viscosity, start with the barrel temperature. The molding shrinkage range and shrinkage rate are large, the directionality is obvious, and shrinkage holes, deformation, etc. are prone to occur.

It is best to use PA recycled materials no more than three times to avoid discoloration of the product or a sharp decline in mechanical and physical properties. The application amount should be controlled below 25%. Excessive use will cause fluctuations in process conditions. The mixture of recycled materials and new materials must be dried.

When starting up, the nozzle temperature should be turned on first, and then the barrel should be heated. When the nozzle is blocked, do not face the nozzle hole to prevent the melt in the barrel from being suddenly released due to pressure accumulation, which may cause danger. The screw should be emptied when the machine is shut down to prevent the screw from being broken during next production.

Using a small amount of release agent can sometimes improve and eliminate defects such as bubbles. The release agent for nylon products can be zinc stearate, white oil, etc., or it can be mixed into a paste and used. The amount must be small and even when used to avoid surface defects of the product.

The post-processing of nylon products is to prevent and eliminate residual stress in the products or dimensional changes caused by moisture absorption. There are two post-treatment methods: heat treatment and humidity control.

a). Commonly used heat treatment methods are in high-boiling point liquids such as mineral oil, glycerin, and liquid paraffin. The heat treatment temperature should be 10 to 20°C higher than the use temperature. The treatment time varies depending on the wall thickness of the product. If the thickness is below 3mm, it is 10 to 15 minutes. , the thickness is 3~6mm and the time is 15~30 minutes. The heat-treated products should be slowly cooled to room temperature to prevent the sudden cooling from regenerating stress in the product.

b). Humidity control treatment: Humidity control treatment is mainly carried out on products with relatively high environmental humidity. There are two methods: boiling water humidity control method and potassium diacetate aqueous solution humidity control method (the ratio of potassium acetate to water (1.25:1, boiling point 121℃), the boiling water humidity control method is simple, as long as the product is placed in an environment with a humidity of 65%, so that it reaches the equilibrium moisture absorption capacity, but it takes a long time, and the potassium acetate aqueous solution humidity control method is The processing temperature is 80~100℃ potassium acetate aqueous solution humidity method. The processing time mainly depends on the wall thickness of the product. When the wall thickness is 1.5mm, it takes about 2 hours, 3mm takes 8 hours, and 6mm takes 16~18 hours.