Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

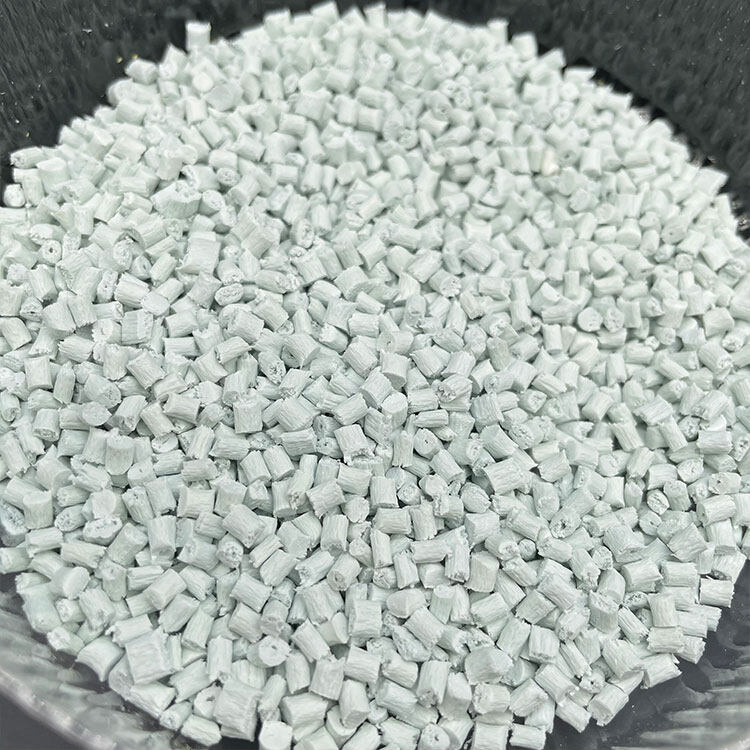

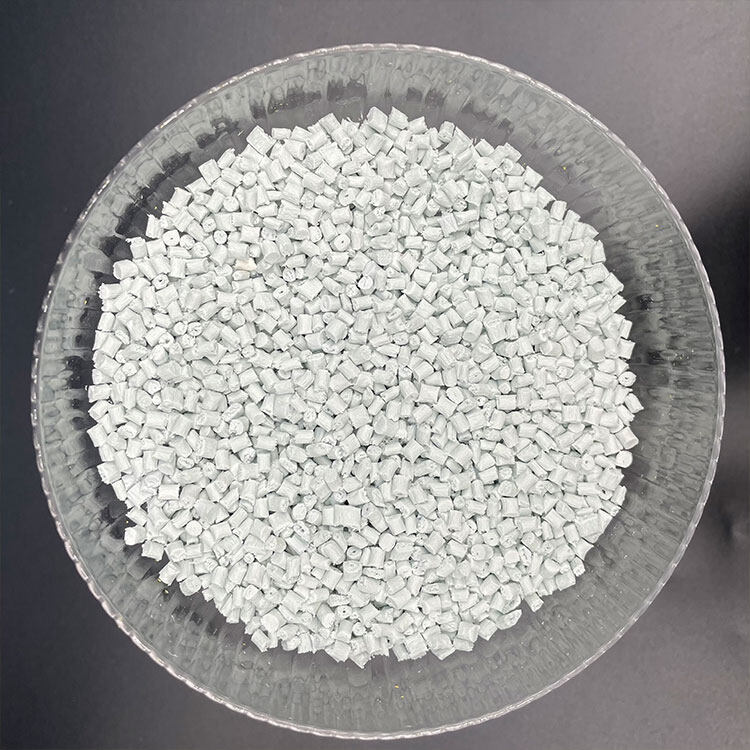

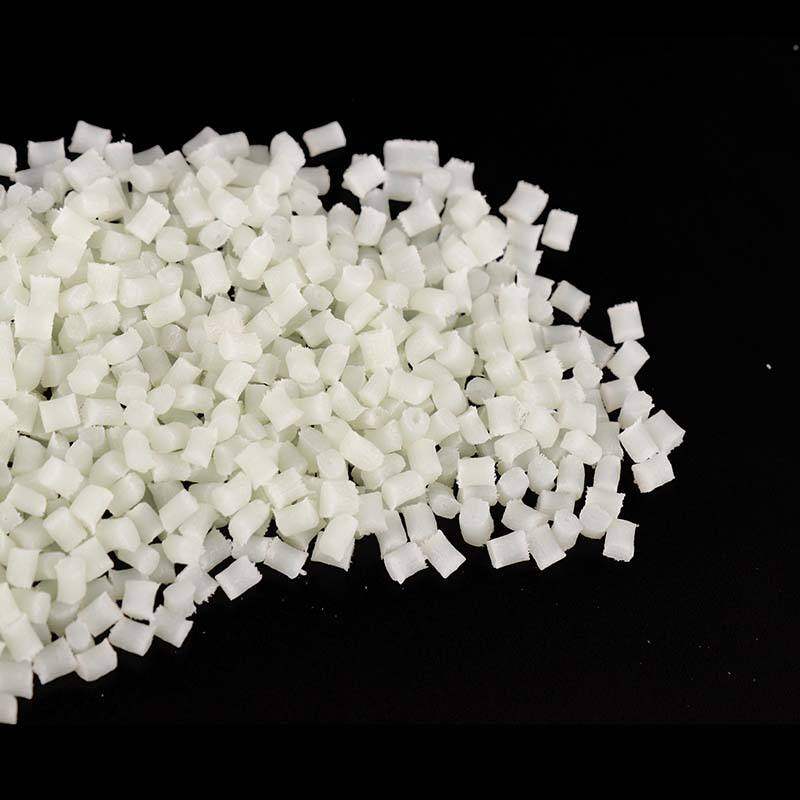

PA66 GF30 F060730

Glass Filled: 30%

(Custom materials available according to your Technical Data Sheet)

- Les détails du produit

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Technical Data Sheet of PA66 GF30 F060730 Nylon Polyamide 66

Halogen-Free Enhanced Flame-Retardant PAPa66 Resins (halogen added is also available)

PA66 GF20/ PA66 GF30/ PA66 GF35/ PA66 GF40/ PA66 GF50

PA66 GF30 is a high heat glass-reinforced polyamide 66 that is widely used in various industries. The addition of 30% glass fiber reinforcement to the polyamide 66 resin enhances its mechanical strength, rigidity, and resistance to heat and impact.

The outstanding heat resistance of PA66 GF30 makes it an excellent choice for applications exposed to elevated temperatures. It retains its mechanical integrity and dimensional stability even under challenging operating conditions, ensuring reliable performance.

Also referred to as nylon PA66 GF30 or polyamide PA66, PA66 GF30 exhibits exceptional chemical resistance, electrical insulation properties, and excellent creep resistance. These characteristics make it suitable for demanding industrial environments.

PA66 GF30 granules are well-suited for injection molding processes, allowing the production of complex and precise parts with ease. The material's excellent flowability and moldability ensure efficient manufacturing and cost-effective production.

In the high heat glass reinforced polyamide 66 market, PA66 GF30 is extensively utilized in automotive components, electrical enclosures, and industrial equipment. Its superior strength and stiffness contribute to enhanced performance and durability in these applications.

With TOPONEW's dedication to quality, our PA66 GF30 granules meet stringent industry standards. We ensure consistent material properties and quality control to deliver reliable and high-performance products that exceed customer expectations.

Partnering with TOPONEW means gaining access to exceptional materials for your injection molding needs. Our PA66 GF30 granules offer versatility, durability, and enhanced mechanical properties, enabling you to meet and exceed the demands of your projects.

Choose TOPONEW for your PA66 GF30 requirements and experience the perfect balance of high heat resistance, strength, and dimensional stability. Trust our expertise and superior materials to bring excellence to your injection molding applications.

PA66, also known as Nylon 66, is a type of polyamide synthetic polymer. It is produced through the polymerization of hexamethylenediamine and adipic acid. The composition of PA66 consists of:

-

Polymer Chain: PA66 is made up of repeating units of hexamethylene diamine and adipic acid, which form a long-chain polymer structure.

-

Chemical Structure: The repeating unit in the polymer chain consists of an amide group (-CONH-) that contributes to its high strength and toughness.

-

Crystalline Regions: PA66 typically exhibits a semi-crystalline structure with ordered regions (crystalline) and disordered regions (amorphous).

-

Polymer Additives: Depending on the specific application, PA66 formulations may also contain additives such as stabilizers, plasticizers, flame retardants, or reinforcements to enhance certain properties.

The composition and structure of PA66 contribute to its excellent mechanical properties, high strength, thermal resistance, and chemical resistance, making it a versatile engineering plastic used in various industries.

PA6 stands for Polyamide 6, which is also known as Nylon 6. It is a type of synthetic polymer that belongs to the polyamide family. Here are some key points about PA6 material:

-

Composition: PA6 is produced through the polymerization of caprolactam monomer. The repeating unit in the polymer chain is made up of six carbon atoms, hence the name Nylon 6.

-

Properties: PA6 is known for its excellent mechanical properties, such as high tensile strength, good impact resistance, and toughness. It also has good abrasion resistance and low coefficient of friction.

-

Applications: PA6 is commonly used in various industries for applications such as automotive parts, electrical components, textiles, consumer goods, and more.

-

Processing: PA6 can be processed using various methods including injection molding, extrusion, and blow molding. It can also be easily recycled, making it a more sustainable option compared to some other materials.

PA6 is a versatile engineering plastic that finds a wide range of applications due to its desirable combination of properties.

Download

-

PA66GF30.pdf

Download PA66GF30.pdf